UHMWPE CHOPPED FIBER

Product Description

UHMWPE Fiber is the latest generation of high-performance fiber, with characteristics of light weight, high strength, high modulus, high resistance to fatigue and corrosion, etc. UHMWPE short fiber is chopped from long fiber.

Properties

- Mechanical Property

- Chemical Resistance

- Age Resistance

- Fatigue Resistance

- Cold Resistance

Technical Data Sheet

材料 Material | 单位 UOM | 超高分子量聚乙烯纤维 Ultra-high Molecular Weight Polyethylene Fiber(UHMWPE fiber) |

|---|---|---|

密度 Density | g/cm³ | 0.97-0.98 |

长度 Length | mm | 12/18 |

单丝横截面 Filament Cross Section | / | 近似圆形 Round |

单丝直径 Filament Diameter | μm | 24 |

熔限 Melting Range | ℃ | 144-152℃ |

拉伸强度 Breaking Strength | / | 3.0 Gpa/31 cN/dtex |

拉伸模量 Breaking Modulus | / | 116 GPa/1200 cN/dtex |

断裂伸长率 Elongation at Break | / | 1-3% |

Performance of UHPCC

Ultra-high Ductility

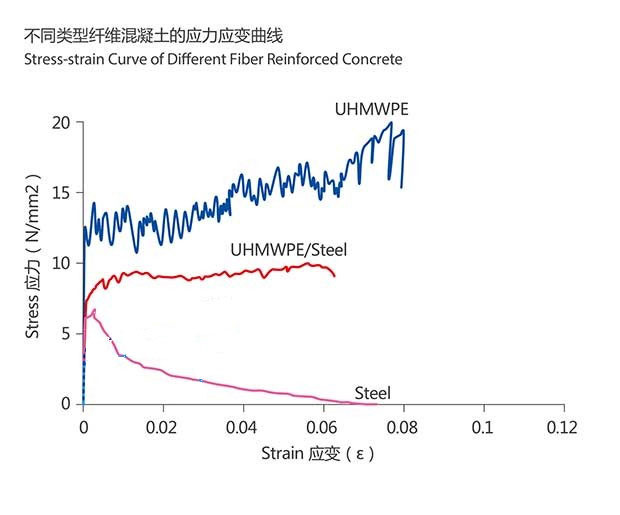

The elongation at break of ordinary concrete level is only 0.01%, and then the gure improved to 3% through fiber reinforcement, but with UHMWPE short fiber, the elongation at break of concrete can reach 8% or even higher. Different from penetrating crack on ordinary concrete at break, the UHPCC generates fine saturation cracks when it bears growing force, and that make UHPCC maintain longer working strength, and the same time provide better protection for steels inside the concrete.

Ultra-high Strength

UHPCC has great strain strengthening performance, and its ultimate tensile strength can reach 20MPa, while maintaining a tensile ductility of 8-10%. Its bending tensile strength can reach 30MPa and axial compressive strength can reach 120MPa, a two times’ improvement compared with common fiber reinforced concretes.

Fatigue Resistant

The concrete structure is prone to be damaged due to long-term stress and strain. With UHMPWE short Fiber, it can not only reduce the strain range of the concrete itself but also reduce the strain burden of internal steel structure. At the same time, due to the excellent fatigue and wear resistance of UHMWPE fiber, the wear resistance on the surface of concrete will be effectively improved, thus greatly improving the serving life of the over-all structure.

Application OF UHPCC

UHPCC can be used with no steel or less steel due to its characteristics of high strength, high ductility, and high toughness. To reach the same strength requirement, it can help building structures achieve lighter weight or smaller volume, making it the best choice for lightweight concrete structures, thin wall structures and special form buildings. But for most conventional buildings, UHPCC’s value lies in which it can greatly improve the buildings’ ability to resist crack, deformation, impact and fatigue, granting buildings upgraded safety, durability and seismic level. So it can apply in Bridge deck and pier / Bridge expansion joint / Dam / Port and pier / Airport runway / Delicate buildings / Aseismic Structure / Cold Area Construction.