QuanCles® UHMWPE Fabric Reinforced PVC Membrane

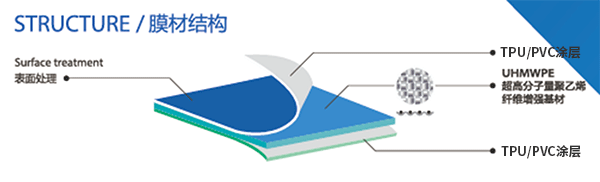

Product Structure

QuanCles® is an advanced flexible composite membrane developed by Quantumeta AMT which is claimed as the strongest membrane in the world because it is reinforced by UHMWPE fabrics. QuanCles® is made by lamination of thermal plastic polyurethane (TPU) or poly vinyl chloride (PVC) onto UHMWPE fabrics with high surface energy. Combine the property of UHMWPE and TPU or PVC, QuanCles® is a super membrane of high strength, low weight, cut resistance, tear resistance. It brings super performance to its application product, like tents, bag, airbag, dome and etc.

Product Description

QuanCles® woven UHMWPE Fabric Reinforced PVC membrane exhibits a unique combination of high tensile strength and provides multidirectional reinforcement, ensuring uniform stress distribution and resistance to tearing, bursting, and puncture under dynamic loads. This composite membrane’s design principles rooted in interfacial optimization and modular functionalization, The matrix performance with ultralight, high tensile strength, flexible and foldable, exceptional tear and burst resistance, anti-aging properties.

This product can be customized according to customer aesthetic needs, such as weight, width, roll length, surface treatment and other indicators to meet the diverse needs in different application markets.

Properties

- Ultralight

- High Tensile & Tear Strength

- Flexible and foldable

- Cut-Resistance

- Exceptional Tear

- Burst Resistance

- Anti-aging

Technical Data Sheet

特性 Property | 单位 UOM | 海格隆®-9010 QuanCles®-9010 | 检测标准 Test standard |

|---|---|---|---|

基布 Reinforcement | 超高分子量聚乙烯纤维织物 UHMWPE Fabric | ||

涂层树脂 Surface Resin | PVC | ||

颜色 Color | Customized | ||

面密度 Areal Density | g/m² | 1000±50 | ISO 2286-3 |

厚度 Thickness | mm | 1.1±0.05 | ISO 2286-2 |

幅宽 Width | m | 1.2~1.6 | ISO 2286-2 |

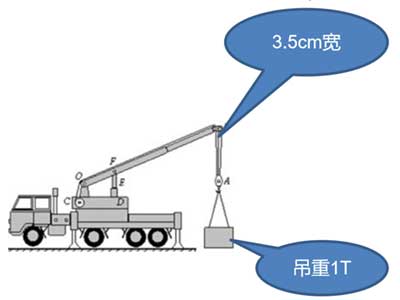

拉伸强度 Tensile Strength | N/5cm | 9000/8500 | ISO 1421 |

断裂伸长率 Elongation | % | < 10 | ISO 1421 |

撕裂强度 Tear Strength | N | > 1200 | ISO 4674-1(裤型) |

顶破强度 Bursting Strength | kN | / | GB/T 14800-2010 |

剥离强度 Peel Strength | N/2.5cm | / | GB/T 2791-1995 |

阻燃等级 Flame Resistance | / | / | GB 8624-2012 |

Performance Introduction

Tensile Testing

The ISO 1421 standard for the determination of the tensile strength of fabrics coated with rubber or plastics at ambient temperature and defines the mechanical characteristic values. Comparative testing demonstrates that the UHMWPE Fabric Reinforced PVC membrane materials show ≥2x (TWICE) higher tensile strength than conventional membranes at equivalent weight class.

Tear Testing

The testing evaluates a material's resistance to tearing propagation under controlled conditions by using ISO 4674-1(Trouser-shaped) method B. It’s critical for assessing durability in applications.

Comparative testing demonstrates the UHMW fiber reinforcement PVC membrane boosts tear resistance by >300% compared to conventional membranes at equivalent weight.

Perforation Method for Strength and Elongation Testing

Perforated tensile membrane tests the strength and elongation of membrane materials after perforation damage occurs—a critical assessment for applications where puncture resistance and post-damage structural integrity are essential.

It was verified the Perforation testing of UHMWP reinforced PVC membrane, the strength and elongation can reach over 80% of the body, 5 times of conventional membrane with equivalent weight.

Puncture testing (Mullen Burst Tester)

Puncture testing is a way of determining the puncture resistance of materials. During the test upon GB/T14899-2010, The top-pressing rod applied a constant displacement rate to penetrate the sample, reaching a force exceeding 38 kN (the upper limit of the testing equipment's detection range). This force was five times greater than that measured for conventional membrane materials.